SEC Heat Exchanger Image Gallery

Here are some pictures of the various heat exchangers we have manufactured and installed for some of our customers. We will help you with all aspects of your installation and are able to custom craft solutions for all your energy transfer needs from the very small to the very large. Check back often for new additions to the image gallery and feel free send us some pictures of your heat exchanger installation to add to the gallery.

(NEW!) Two titanium heat exchangers bound for a food processing facility.

(NEW!) District heating in Yellowknife 600-kW very close approach temperatures.

(NEW!) Heat Exchanger installed in the Library of Congress Washington DC.

(NEW!) Final cleaning and packaging of heat exchangers prior to shipment to Library of Congress Washington DC.

(NEW!) Repair consisting of complete new stainless steel shell.

Completely metric dimensions. Canadian Coast Guard vessel Louis St. Laurent.

(NEW!) Brazed plate heat exchanger used for cooling beer wort.

Cooling home brew beer wort from scalding hot to less than ambient in 1 pass. “We never know where our heat exchangers end up and can't wait to test out our customers beer!”

(NEW!) Made for the State of Texas Wildlife Department.

This heat exchanger has titanium plates and titanium connections. The frame, tightening rods and guide bars are Gr. 304-L stainless steel. The heavy nuts are brass.

(NEW!) Cleaning of 'Semi-welded' plate heat exchanger at a lobster processing plant, 'Eastern Canada'.

(NEW!) In a 17 week time frame SEC delivers a 13 mW gas cooler to Shell Canada.

(NEW!) Large gas cooler from SEC installed for Shell Canada.

(A) An all stainless 150 psi steam/oil heat exchanger.

(B) Shell and coil tube heat exchanger for plant.

(C) Brazed plate heat exchanger used for engine oil heater.

An engine heater which keeps the engine oil warm between races or heats. The black box has one of our M14-20 brazed plate units in it, this heats the oil by using a small tank of glycol heated with an electric heater. The glycol is pumped thorough the heat exchanger (hot side) and the oil is on the cold side of the HEX plates.

(D) 4 pass copper shell and double wall U-tube unit designed for use with heating systems.

(E) An SEC designed and fabricated energy station.

(F) Very large shell and tube heat exchangers being loaded for delivery by truck.

(G) Heat exchanger skid setup using an SEC shell coil model exchanger.

(H) Titanium exchanger setup for a ground source heat pump from a salt water well 150 psi.

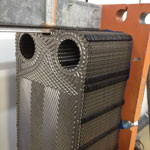

(I) Large plate and frame heat exchanger for cooling application.

(J) SEC Heat Exchangers demands the highest quality welding.

(K) SEC AMDX18-42 PlateMAX orange heat exchanger at Boulder Hydronics.

(L) 7 wide gap SEC plate and frame heat exchangers heading for Western Canada.

(M) Dimple jacket for heating a beer brewing tank.

(N) Shell and titanium tube heat exchangers with Monel clad heads, tube-sheets and connections.

(O) Three small titanium heat exchangers used for heat recovery from a heat

pump.

(P) Two shell and coil tube units steam to liquid application.

(Q) Large monel clad heat exchangers.

(R) Plate and frame heat exchanger in gas / oil processing facility in southern USA.

(S) 1 of 5 stainless steel coils, 6 ft diameter.